SeatradeMaritime: Can watered-down fossil fuel and tidal power decarbonise shipping?

Innovation is a live and well in the green shipping sector as companies seek solutions to meet decarbonisation targets.

The IMO’s extraordinary decarbonisation meeting is due to start in less than two months, but as the path to green Nirvana remains muddied, here two innovation pathways light the way.

Currently, LNG is the preferred alternative fuel for most new vessel orders as shipowners look to reduce emissions using gas and diesel, with a view to modifying engines to a net zero fuel further down the road.

In a recent article, DNV marine CEO Knut Orbeck-Nilssen argued that the stringency of the IMO’s greenhouse gas fuel intensity (GFI) requirement, which would come into force in 2028 and supersede the FuelEU Maritime regulation, will accelerate decarbonisation.

Orbeck-Nilssen complains: “Unlike the FuelEU Maritime regulation, which grants LNG-fuelled ships a clear compliance pathway through 2039 depending on the combustion technology, the IMO framework offers no such accommodation, even in its initial phases.”

According to Orbeck-Nilssen LNG can “serve as a bridge to low-greenhouse gas fuels like bio-LNG and e-LNG, which can be burned on existing LNG-fuelled vessels”.

Interestingly, DNV client Hapag-Lloyd began a programme of vessel optimisation that will reduce emissions and increase capacity on its ships in 2021, in partnership with the class society.

Related:Intercargo and GCMD sign two-year decarbonisation partnership

On 28 August, DNV’s Jan Olaf-Probst, executive VP business development, wrote about the measures being taken, new hull profiles, new propellers that will accommodate slower steaming, increased draft and higher lashing bridges.

“All of these measures have short payback times, and they’re highly interdependent,” said Probst.

Other operators have assessed that meeting 2030 regulatory targets can be achieved through efficiency modifications, reducing fleet emissions by over 50% in some cases, with a view to achieving 2030 and 2035 emissions targets without embracing a new fuel.

For these operators, innovation and efficiency are the keys to the maritime transition to low or zero carbon fuels with substantially reducing emissions from the more than 60,000 ships already in operation ahead of total decarbonisation critical.

Some 80% of maritime emissions come from tankers, bulkers and container ships and so a method of turning the large deepsea fleet into jolly green giants is necessary. With limited amounts of biofuels available, one method could be another fossil fuel treated to produce a fuel called MSAR, or Multiphase Superfine Atomised Residue.

Produced by Quadrise, MSAR and BioMSAR are effectively blended fossil fuels, 70% heavy hydrocarbons and 30% water with cationic surfactants added creating fuel droplets of between one and 10 microns, much smaller than standard droplets of around 100-microns, meaning it burns more efficiently, explained Quadrise CTO Jason Miles.

Related:On the fairway to vessel efficiency

“MSAR is burned at a lower temperature, we inject our fuel at about 70°C compared to 100 plus for high sulphur fuel. And that means that everything happens at a lower temperature, giving you get better efficiency in the engine and that’s really where it starts,” added Miles.

According to Miles, Quadrise has maintained a 10% price differential between HFO and MSAR, with the blended fuel reducing carbon emissions by up to 9% on two-stroke engines, but around 6% on average, and 3-5% on four-stroke engines, according to Quadrise.

In addition, MSAR and BioMSAR can reduce emissions costs, claims the company, while other benefits include a 25-30% reduction in NOx, and particulates are drastically reduced, with the fuel “burning with a white stack, like a gas,” said Miles.

MSAR was tested on a Maersk vessel, with a 96-bore, 12-cylinder Wărtsilă Flex engine, BioMSAR is now about to undergo similar tests with MSC, bizarrely on the same ship after the Swiss line acquired the vessel from Maersk.

BioMSAR has added glycerine and that improves the performance of the fuel and its efficiency.

Related:UK government unveils £30m investment in shipping decarbonisation

Quadrise are confident that BioMSAR will be popular with vessel operators and it is in the process of establishing production and bunkering sites, beginning with the Mediterranean.

“We’re basically putting a system in Antwerp [port] using Cargill’s assistance, they will supply the feedstocks, and we’ll then convert that into BioMSAR, initially for the MSC trial,” explained Miles.

He added, “Ideally if we can get these agreements signed soon, then that’ll be up and running by the end of the year and then Antwerp will start to supply trial volumes of this product in January 2026.”

Meeting the increasingly stringent regulatory levels from 2030 onwards will require far greater reductions in carbon emissions, although Miles is confident that evolutions of MSAR and BioMSAR can meet increasingly stringent regulations up to 2040.

To achieve the more challenging post-2040 targets, innovations that offer zero- or net-zero-emissions will need to be adopted, and the development of these technologies has already begun.

Greater vessel efficiencies will be necessary, but wind assisted power and other zero emission technologies will also be required. Wind power can offer substantial savings with new sail designs on particular trade routes and in certain regions of the globe.

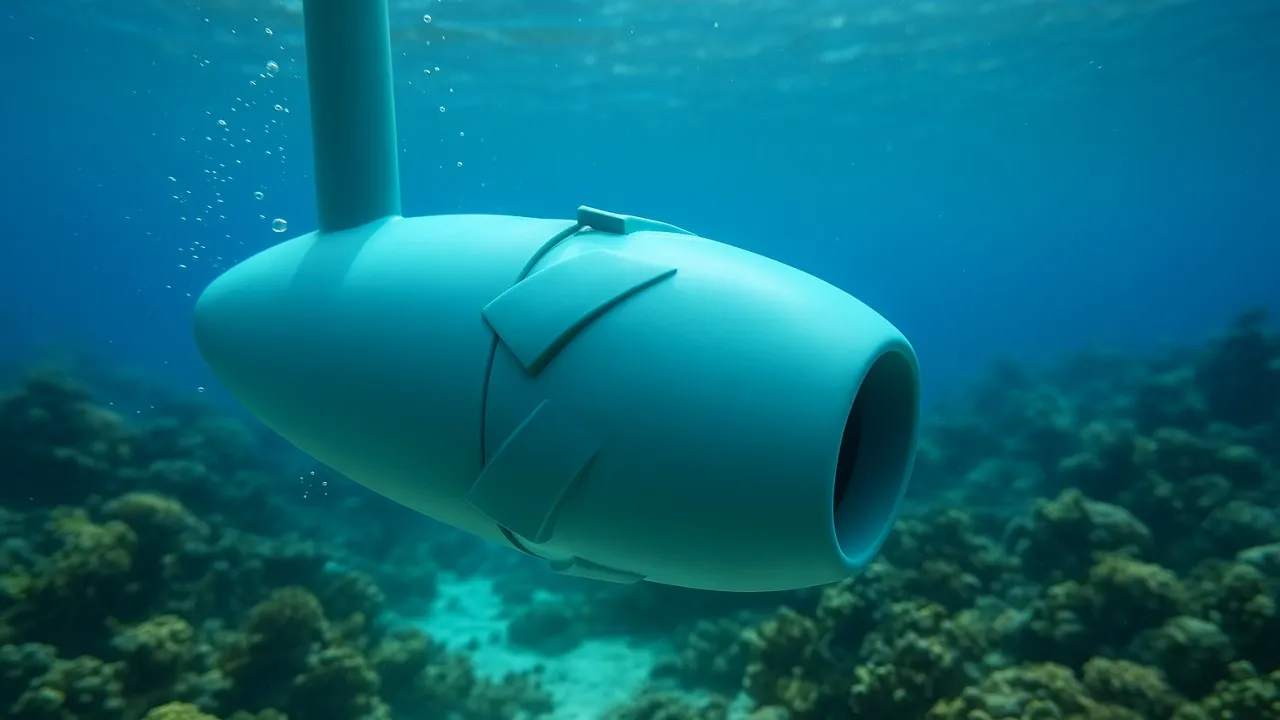

Another zero-emission power source is tidal power, and Propel and Power has bladeless turbines under development and is keen to show the technological possibilities of its innovation, which has been patented in the UK and is patent pending in the US.

Propel and Power is a company created by an IT engineer, Jagadish Rao Raghavendra and his partner and design engineer Drago Senic. The company’s tidal power system is designed to produce up to a megawatt of electrical power per turbine, 100MW/hectare, 24hours/day using tidal energy.

The turbine is shaped like a jet engine, but with a void inside where water flows, rotating the central element to provide the energy required.

Designer Drago Senic explained: “Water is ejected through these nozzles [on the central part of the turbine] oriented around the circumference of the rotor, at nearly 90°, and this is how it produces useful torque.”

This same system can be used to power ships, either by fixing turbines to ships or by producing green energy, such as hydrogen from fixed offshore power stations.

The system is a modular system, which means the power can be increased by adding turbines onto the ship, or to the offshore power plant.

Turbines can be fixed to the ocean floor, to a ship or to an offshore floating platform, generating power by simply sitting in tidal currents. It provides weatherproof land free power generation and can be retrofitted to ships with tailored integration systems.

“By using this turbine as a propulsion device, it will actually be more efficient than a traditional propeller,” explained Senic, and the design allows the turbines to be placed close to each other without effecting the efficiency.

Propel and Power turbines are in the development stage, with a demonstrator currently under construction with Cambridge University partnering the company to develop the power source.

Using these existing and developing technologies the pathway to zero emission energy via greater efficiency and new designs can bypass the requirement for new fossil energy in transition, substantially reduce emissions through the development periods and pay for the next generation of power. new growth drivers, digital intelligence and green low-carbon development, to expedite the synergetic development of core container shipping business and digital supply chain business.”

After taking delivery of a number of vessels ordered, the company’s own operated fleet currently comprises 557 vessels with a total capacity of over 3.4 million teu. The company possessed new orderbook with a total capacity of nearly 910,000 teu, strengthening its first-tier ranking in the industry in terms of shipping capacity.

Related:CMA CGM secures bio-LNG supplies from Vanguard Renewables

The company’s main business remained stable during the first six months. The container shipping business handled 13.28 million teu, up by 6.59% year-on-year. Freight volumes on Trans-Pacific routes, Asia-Europe routes, Intra-Asia routes, other international routes (including Africa/Latin America) and China’s coastal and inland routes increased by 4.72%, 3.88%, 5.21%, 11.95% and 9.53%, respectively.

“Looking ahead, the container shipping industry is expected to remain complex and volatile. The domino effects of economic and trade policies coupled with ongoing geopolitical tensions, the reshaping of competitive landscape triggered by technological and green transformation, and the frequent occurrence of various unforeseen events, all may have a profound impact on the overall market development,” stated the company.

Related Posts